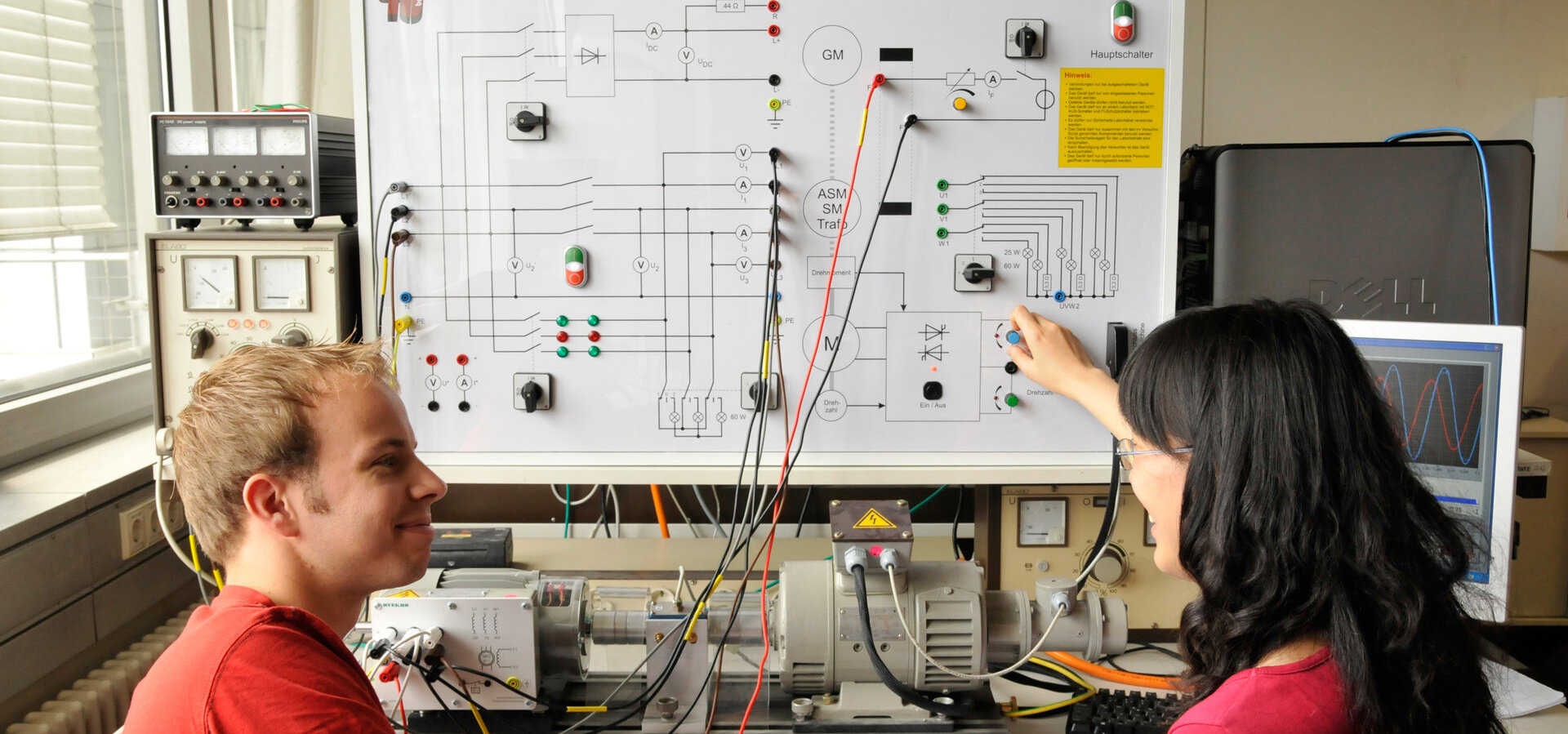

Fachgebiet Elektrische Antriebstechnik

Aktuelles

Kontakt

Dr. Thomas Wörther

Sekretariat des Fachgebiets

| Einrichtung | FG Elektrische Antriebstechnik |

|---|---|

| Sekretariat | EM 4 |

| Gebäude | EMH |

| Raum | EM 162 |

| Adresse | Einsteinufer 11 10587 Berlin |

| Sprechzeiten | Di und Do, 12:00 - 15:00 Uhr |

© Ulrich Dahl/Pressestelle der Technischen Universitaet Berlin

© Ulrich Dahl/Pressestelle der Technischen Universitaet Berlin